Daryl Oster: Evacuated Tube Transport Will Bring Space Travel on Earth

Socrates / Podcasts

Posted on: June 24, 2013 / Last Modified: September 27, 2021

Podcast: Play in new window | Download | Embed

Subscribe: RSS

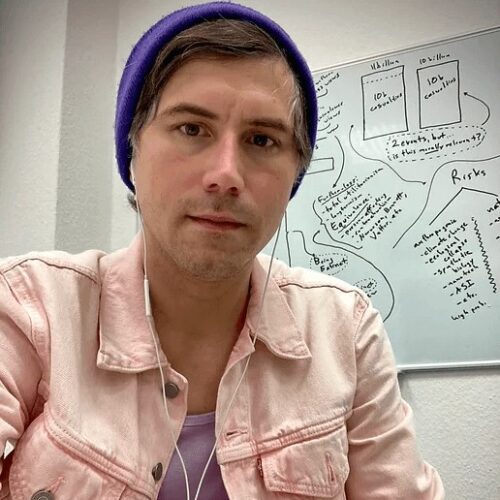

Daryl Oster is an inventor and engineer who wants to bring space travel to Earth. The idea is called ET3 – Evacuated Tube Transport Technologies. Oster is the CEO of ET3 and his company “uses an open consortium business model to share information resulting in co-operative benefits.” The goal is nothing less but building a radically new high-speed global network of transportation that will be cheap to use and maintain; safe not only for passengers but also for the environment; accessible to and affordable for everyone on Earth; quiet and fast (with speeds eventually reaching 4,000 mph).

Daryl Oster is an inventor and engineer who wants to bring space travel to Earth. The idea is called ET3 – Evacuated Tube Transport Technologies. Oster is the CEO of ET3 and his company “uses an open consortium business model to share information resulting in co-operative benefits.” The goal is nothing less but building a radically new high-speed global network of transportation that will be cheap to use and maintain; safe not only for passengers but also for the environment; accessible to and affordable for everyone on Earth; quiet and fast (with speeds eventually reaching 4,000 mph).

During my conversation with Daryl Oster we cover a variety of interesting topics such as: what is ET3 and how did it come to be; how, by removing friction, evacuated tube transport will bring space travel to Earth; why automating ET3 is easier than automating robot cars; the optimum degree of vacuum required to achieve the highest efficiency of transportation; the costs associated with the R&D and building the network; ensuring safety and dealing with malfunctions; why evacuated tube transport is cheaper and better than the alternatives; Daryl’s unique business model; the current state of development and projects both in the USA and abroad; why the major obstacles are political and legal and not technological; the biggest misconceptions about ET3; why innovators are the ones with knife wounds on their backs; why the greatest benefits of the project are social; the technological singularity…

As always you can listen to or download the audio file above or scroll down and watch the video interview in full. To show your support you can write a review on iTunes, make a direct donation, or become a patron on Patreon.

What is Evaculated Tube Transport?

Who is Daryl Oster?

Daryl Oster conceived the basic principals of ET3 in the 1980s, refined and founded the company in 1997, and received the first technology patent in 1999. The company uses an open consortium business model aimed at building a global network of evacuated tube technologies that will bring space-like friction-less travel on Earth.